Metallurgy

-

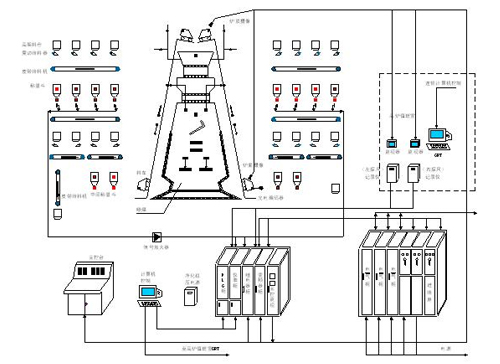

The three electric integration control system of blast furnace system is to break the traditional division boundaries of computer, PLC and DCS. Through the control of blast furnace body, raw material and fuel system, feeding system, air supply system, slag and iron treatment system and gas purification treatment system, an integrated automation system of three electric integration is formed. The whole process can be summarized as follows: under the condition of low energy consumption as far as possible Through the controlled reverse movement of charge and gas flow, the process of reduction, slag making, heat transfer and slag iron reaction can be completed efficiently, and the liquid metal products with ideal chemical composition and temperature can be obtained.

Blast furnace control mainly includes blast furnace body control, feeding and batching control, hot blast stove control, dust removal system control, etc. The main purpose of the control is to ensure that the burden is proportioned correctly and loaded into the furnace in a certain order in time; the burden is controlled to drop evenly; the burden distribution is adjusted and kept in good contact with the hot coal flow; the proper thermal state of the whole blast furnace is maintained.